My To Do Pile - Part 1

It's a beautiful story - a boy grows up making jam with his mother from currants they pick themselves in their backyard. As the boy grows up, he hones his craft with years of practice, always putting up jars of delicate and sumptuous preserves made with only the best fruit at the height of their season. Eventually, the legend of his glorious talents spreads of its own accord and so he starts a small artisan jam company with his wife. And now, years later, he spends all of his working days smelling fruits deeply and lovingly tending to copper pots of steaming jam, only making what moves his spirit.

Occasionally he sells a few jars to a local fromagerie for $37 apiece.

Not me

Not me

Instead, this is what the current "to do" list looks like of your favorite jam maker (which I'm assuming is me because you're here reading my blog):

Yikes.

As much as I cringe to admit it, this pile of stuff pretty well captures what my job looks like. It's such a good representation of my job/life, I thought I'd take some time to explain just what's in this pile and use it to give you a sense of what the day to day is actually like for an owner of a small artisan food company. Spoiler alert: it's a little crazy sometimes. :)

There's so much to unpack here that it's going to take a few blog posts to get through it.

Ok, let's start with the red flier you see right at the start, which is advertising the benefits of a machine called "The Dispense-a-matic." A pretty amazing name if you ask me. I picked this up at a trade show some months back and it has been floating around my bag, home office, work office and the trunk of my car ever since.

Now, I grabbed this flier because we've been putting the labels on our 1.5 oz preserves (like the little jam jars you get at a hotel) for the last ten years. As of today, we have labeled 165,127 jars this way. That's a lot of stickers to put on by hand and, frankly, it's kind of annoying to do.

The jars are small so you've got to be very precise in putting the label on straight. Otherwise, when you wrap the label around, it's super crooked. We make a ton of these jars because they're adorable and people love them. So, I've been looking for a machine that could help us make the process more automated and less tedious for our employees.

I've been looking since about 2010.

Now, I should say, we have a labeling machine and we use it to label the lion's share of our products - all of our 6 oz jars of preserves and 8 oz syrup bottles. A few years back, we decided to purchase the fully automated labeling machine you see in this fascinating 20-minute training video I created. You also get to see me try and make a training video while simultaneously take care of a 6-month-old:

When we got this machine, we hoped it would solve all of our labeling problems. I mean, it's got lasers, two conveyor belts, serpentine threading diagrams and cost much more than my car. How could it not work perfectly? I assumed that it would not only label everything effortlessly, but also rotate inventory, mop the floors and make the staff espressos while we checked our stock portfolios and smoked cigars in velvet jackets.

Alas, this was not the case.

Even though this machine cost more than we spent to build out the entire kitchen that we started the company with, it couldn't put straight labels on our small jars. The technician that we had to fly up to Wisconsin to help us set up and install the machine tried and tried to get the labels to go on straight, but couldn't do it. Stumped after working on the problem for a few hours he said to me in exasperation, "I mean, I didn't even know we made machines this small, so maybe I'm not the guy to fix this." Well, it turns out no one at the company was "the guy to fix this" and so 5 years later we're still labeling by hand.

This is a part of a larger problem that we've dealt with since day one. There just aren't that many small food manufacturers out there, so there isn't a robust industry of companies making things that they need. The fundamental logic of our economy is that one achieves efficiency and cost savings through scale. But when you're a small industry made up of small producers, by definition you don't have scale and so equipment for people like us is either non-existent or very expensive.

So, you only have a few options:

- Invest a bunch of your own money to build a facility with expensive equipment beyond what you need.

- Invest a bunch of someone else's money to build a fancy facility.

- Hire someone else to make your product (we call this co-packing in the industry and the vast majority of small food producers go this route).

- Improvise and try to cobble together a mostly workable solution until you're large enough to buy some equipment.

Whether it's because we're control freaks, perfectionists, "dedicated to our craft" or deranged, (we're probably a mix of all of these) we have always insisted on making our own products. We figure we can't very well call ourselves an artisan food company if the jars are actually coming out of some anonymous factory outside of Cleveland. So, co-packing is out.

We don't have a million dollars to build a plant and there aren't too many investors out there who want to fund small artisan food startups.

And that leaves us with option four - improvise and get by until we can afford some equipment that makes whatever our greatest pain point is marginally better.

For us, this has meant everything from getting a friend who has built an unauthorized welding studio in their apartment building's basement to modify an apple corer to zest citrus for marmalade instead (see below)

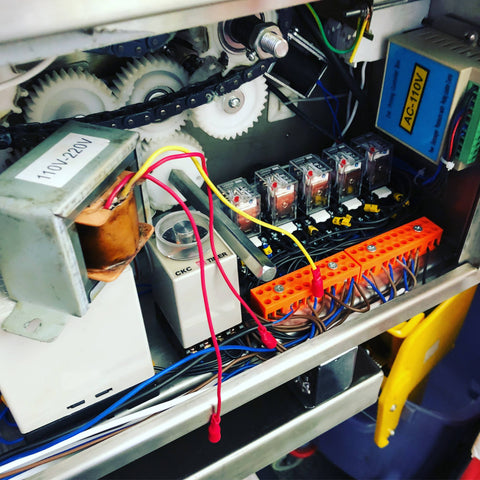

to buying a machine to help package nuts on eBay direct from the factory in China only to find that it immediately bursts into flames when you plug it in!

Here's the picture I texted to tech support in China as they tried to walk me through repairing the machine myself. Spoiler alert - it didn't work and set on fire a second time when I plugged it back in.

It has also meant taking out a huge loan to invest in a labeling machine that costs tens of thousands of dollars only to find that it works for just two out of the three products it was built to label. And, in that case, you end up several years later with a bright red flier for the Dispense-a-matic floating which promises to solve the problem. But, when you read more closely and see that the machine costs $3,995 and would need to be customized for your jars for an additional cost, you just stick it in your bag and carry it around for months, unable to decide if you can afford it or if the pain of labeling by hand justifies the price.

And that's the story of the Dispense-a-matic flier. We often talk about how we do so many things in our production process by hand and in many cases, it makes what we do special because we can focus on details you would lose if the process were automated. But, when it comes to putting stickers on jars, we would have a machine do this for us in a heartbeat. We just can't seem to find a great option to would do this for us. We'll keep looking of course. But for now, we'll keep puttin' those labels on by hand.

Tune in next week for a deeper look at why my "to-do pile" includes so many different notebooks!

Leave a comment